Unlike the Cavemen, we know you want to be able to upgrade the tools you work with and evolve. V10.1 is yet another STRUMIS release to answer our customers’ needs

Waiting around for an upgrade can be a nightmare, especially when you know your competitors are getting regular software updates.

Don’t get left behind in the Stone Age, let STRUMIS show you the future of steel fabrication.

At STRUMIS we pride ourselves on talking to our customers and helping them in anyway we can.

V10.1 is a product of the care and attention that we pay to our customers on a daily basis, as it was solely produced to provide added features and benefits based on our customers’ needs.

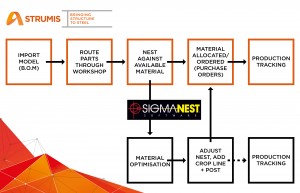

STRUMIS is revolutionizing the future of steel fabrication, not just by ourselves, but along with our customers and partners.

V10.1’s release continues the tradition of providing invaluable enhancements and continuous updates, including an array of functionality and control that is unique to STRUMIS and unmatched in the industry.

These new features are driven by our continuous collaboration and communication with all of our customers, demonstrating our on-going commitment to our customers and the steel fabrication industry worldwide.

New and improved features also mean new and improved benefits. STRUMIS V10.1 ensures better material and time savings, in turn reducing your overheads. In addition V10.1 provides increased efficiency and improved productivity.

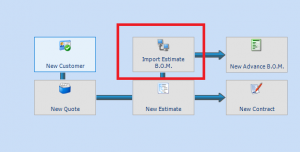

The proof is in the features, V10.1’s new additions provide unrivalled benefits for steel estimating and fabrication:

Change Order Management

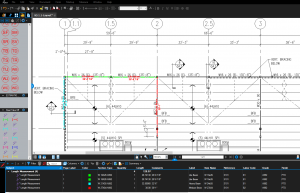

Adding/Editing Existing Nests

Contract Material Rates

Prelim Revisions

Planning Enhancements

User Purchase Order Limits

Improved Plate Girder Management

Batch Update Estimate Lines

Improved Fittings In Estimating

To see all of the new features being used in STRUMIS click the link below to watch a recording of the STRUMIS V10.1 webinar.

STRUMIS V10.1 Webinar