We’re delighted to announce that Canam Group has signed a Corporate Agreement to purchase and implement STRUMIS across their structural and bridge sites.

Canam Group is a leading provider of design and fabrication of construction products, and develops innovative and pioneering solutions by focusing on customer satisfaction, manufacturing effectiveness and digital revolution.

A Detailed Review

Before deciding on how to proceed to more efficiently manage their fabrication and production, Canam Group embarked on a comprehensive and detailed six month review of all available steel fabrication and production software/vendors and assessed offerings against their own in house systems.

This review, which also included a full pilot project, was conducted by a Committee led by two Canam Group Vice Presidents, a General Manager and also included many of Canam Group’s 85 man strong IT team.

The Objective

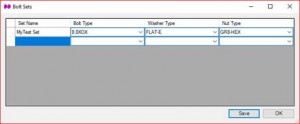

The objective of the Canam Group’s committee was to evaluate the viability of replacing or upgrading their legacy systems with the best solution to provide an integrated BIM compliant solution across all their structural and bridge facilities to facilitate superior communication and multi-site fabrication management. An important additional aspect that the Committee considered was the ability to integrate with four primary systems – Oracle, Tekla Structures, SDS/2 and various incumbent CNC machines.

STRUMIS Selected

Further to Canam Group’s substantial research of all the available choices on the market to deliver a dedicated, multi-site, integrated steel management and production information system, Canam Group selected STRUMIS to be implemented into their sites. Jean Thibodeau, Senior Vice- President InteliBuild and Information Systems at Canam Group commented; “Following a comprehensive 6 month evaluation of the various steel fabrication management solutions available, we decided STRUMIS was the best solution for Canam Group due to a number of key factors. STRUMIS was by far the most comprehensive and feature rich solution available, enabling us to replace multiple legacy systems. Utilizing the STRUMIS Integration Platform and the latest .NET and SQL technology ensured we can integrate STRUMIS with our existing Oracle ERP system, our engineering and detailing software, as well as bar coding, tablet and CNC equipment. STRUMIS will save valuable time handling and managing key operational data across our multiple fabrications facilities.”

Regional Manager commented, “We are extremely proud that the Canam Group team has elected to implement STRUMIS across their sites; this is a significant addition to our prestigious global clientele and we are pleased to continue our outstanding working relations with them.” STRUMIS Technical Director, Simon Inman, commented, “We are delighted to welcome Canam Group and are looking forward to working with them and indeed we have already started implementing STRUMIS.”

About Canam Group

Canam Group is a manufacturing company with over 50 years experience specialising in the design and construction of products and solutions. With close to 3,500 employees, Canam Group is a leading provider of design-build and virtual design construction and a principal supplier in the design and fabrication of construction products, with an annual turnover in excess of US$750 million.

In 2011, Canam Group completed 9,240 construction projects, and operates 20 manufacturing plants, covering an area of 3,112,535 square feet (289,160 m ), with an annual production capacity of 764,000 tons. Canam Group has engineering offices in Canada, the United States, Romania, India and China, and has created alliances in China and France.

By sustaining its leadership role in the digital revolution and construction of energy efficient buildings, Canam Group provides long-lasting products and solutions that endorse development efficiency and productivity.

To see how STRUMIS can benefit your company please visit www.strumis.com