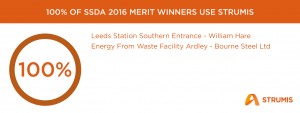

It’s a new year and what better time than at the start of a new year to look forward to your fabrication’s future. Steel fabrication best practices in the 21st Century call for the utilization of technology to stay ahead of the fabrication curve and remain both relevant and profitable in an ever more dynamic industry. The application of software in the steel fabrication process is no longer a nouveau concept, but rather a vital standard fabrication management practice. Software systems, such as STRUMIS, serve the largest and smallest fabricator alike and enable the fabricator to successfully manage their business, ensuring transparency throughout each department, and safeguarding management of resources effectively.

Software integration is a key component to technology in the steel fabrication industry, linking and connecting everything from your accounting software, CNC equipment, detailing software, to your estimating and production management MRP software, such as STRUMIS, for a seamless flow of information to manage commercial aspects of your day to day business. Gone are the days of running multiple programs, separately.

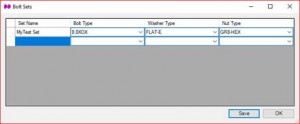

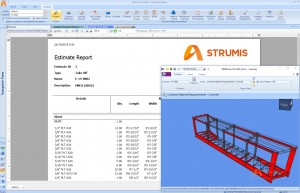

For instance, did you know technology in the steel fabrication industry today will automatically produce from your BIM Model a rapid Bill of Materials and apply all connection details and processes involved in the project cycle, saving you time and providing you unmatched accuracy in your estimate work?

Change management is now effortlessly tracked in today’s technological steel industry, with all potential changes electronically recorded and costed utilizing a simple budget or a full estimate and costs associated to the change order individually electronically tracked to provide financial traceability.

Risk management is systematically overseen, using technology to log all supporting documentation, including RFI’s and correspondence, which can be found at the click of a button. Gone are the headache phone calls wanting to know why a deadline has changed and scrambling to sift through supporting documents.

In the 21st Century, software technology and steel fabrication are synonymous and provide fabricators and detailers a level of control and efficiency never before imagined, even to the level of live integration to enable detailers to make quick, informed decisions to minimize cost and disruption, by seeing real-time status for materials and manufacturing progress. Here’s to a bright and brilliant 2017, may your estimating be seamless and your fabrication workflow streamlined.

Steel fabrication is evolving and STRUMIS is your partner to help you evolve with the time. To see how STRUMIS can bring your steel fabrication into the future visit www.strumis.com