Are you currently using an industry specific solution? STRUMIS talks to hundreds of fabrication companies a year, and we have found that there is a trend of success when industry specific solutions are being used.

We see all too often organisations that struggle with processes and technology solutions when they are generalised for financial management or manufacturing. These solutions do not understand the specific needs around the steel fabrication industry… they don’t understand steel.

When we look at a cross section of the industry we can clearly see that many of the industry leaders in steel fabrication have embraced industry specific technology such as STRUMIS.

Today I would like to quickly break down some of the key areas that are greatly improved with the right technology in place.

In the fabrication market we have to start with the core business issues and stay focused on solving these daily challenges. We have found common business issues across the industry as a whole.

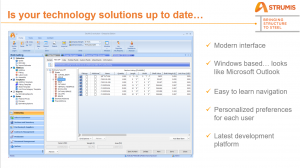

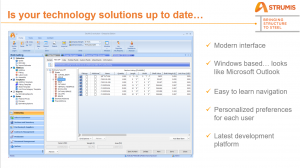

To address these issues with technology we have to start at the top and ask yourself if the technology solutions you are using are current, or dated solutions that have lost relevance over the past 5 to 10 years because they haven’t evolved with the industry by not releasing new versions.

Modern solutions offer better tools that are easier to use and faster to learn and adopt in your organisation. Be honest with yourself here… is your technology solution industry specific and up to date?

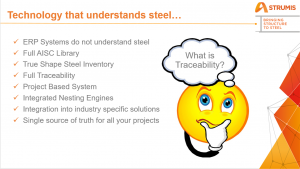

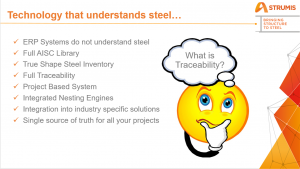

Next, let’s take a look at what industry specific to the steel fabrication market looks like.

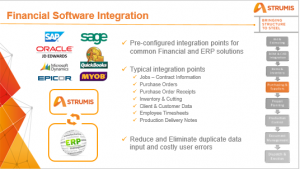

We see countless companies with huge IT spends to further develop an ERP financial system to only end up with a system that still does not understand the complex nature of a steel fabrication project.

These systems are often missing the key items most needed by a fabrication company such as.

- Full Libraries of Steel Goods

- True Shape Steel Inventory Management

- Full Traceability across your project

- Project Based Context needed to proficiently manage your projects

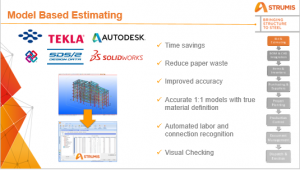

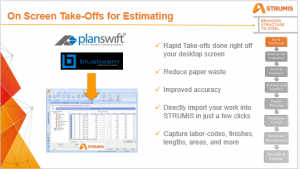

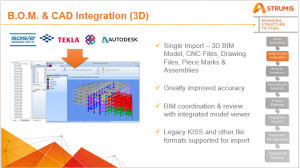

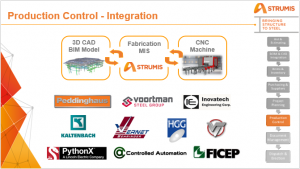

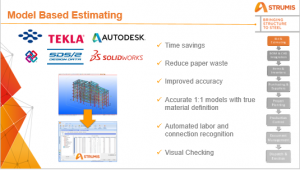

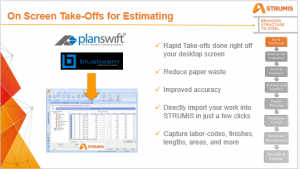

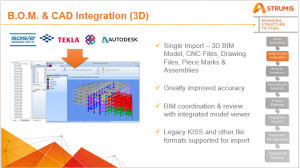

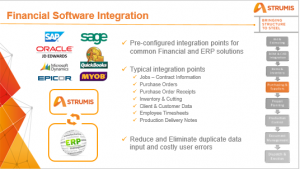

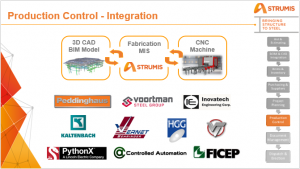

Finally does your technology solution integrate with the industry specific tools and applications utilised to design and execute your fabrication projects?

This is yet another huge technology hurdle in the industry that can be addressed with an industry specific solution. Let’s examine some of these key integration points.

By bringing these industry specific technology solutions together in a seamless environment it helps you to solve critical business issues and drive project success. An industry specific technology solution that is modern and well integrated provides you with a single source of truth around your project information. If you would like to connect and build a technology roadmap together, please reach out to discuss how STRUMIS can help.

Visit www.strumis.com for more information on how STRUMIS can bring all of these benefits to your company.